Cov khoom

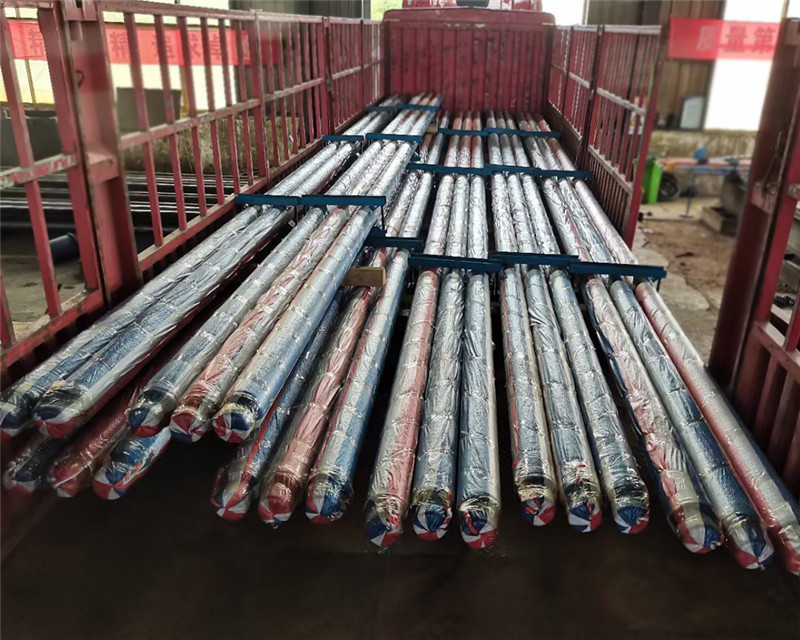

Non-Magnetic Drill Collars & subs

Tsis-Magnetic Drill Collar

Slick Non-Mag Drill dab tshos

Slick Non-Mag Laum dab tshos muab qhov yuav tsum tau muaj qhov hnyav ntawm me ntsis, thiab yuav tsis cuam tshuam nrog lub peev xwm ntawm kev taw qhia.

Spiral Non-Mag Laum dab tshos

Spiral Non-Mag Laum dab tshos yog tsim los tso cai rau thaj tsam ntau dua rau cov dej drilling, thaum muab cov txiaj ntsig ntawm cov hlau tsis-mag rau cov txheej txheem drilling nyuaj.

Flex Non-Mag Drill dab tshos

Flex Non-Mag Laum dab tshos yog nyias thiab hloov tau ntau dua li tus qauv tho dab tshos. Lawv muaj peev xwm ua kom luv luv vojvoog tig, khoov rau siab tsim cov ces kaum, thiab dhau los ntawm doglegs hnyav ua rau lawv zoo tagnrho rau siv nyob rau hauv directional thiab kab rov tav daim ntaub ntawv. Ua los ntawm cov hlau tsis muaj hlau, qhov tho dab tshos no zoo haum rau cov khoom siv MWD vaj tsev.

Khoom Specification

| Kev sib txuas | OD mm | ID mm | Ntev mm |

| NC23-31 | 79.4 ib | 31.8 ib | ib 9150 |

| NC26-35 | 88.9 ua | 38.1 ib | ib 9150 |

| NC31-41 | 104.8 ib | 50.8 ib | 9150 or 9450 ib |

| NC35-47 | 120.7 Nws | 50.8 ib | 915o9450 ua |

| NC38-50 | 127.0 Nws | 57.2 ib | 9150 or 9450 ib |

| NC44-60 | 152.4 ib | 57.2 ib | 9150 or 9450 ib |

| NC44-60 | 152.4 ib | 71.4 ib | 9150 or 9450 ib |

| NC44-62 | 158.8 ib | 57.2 ib | 9150 or 9450 ib |

| NC46-62 | 158.8 ib | 71.4 ib | 9150 or 9450 ib |

| NC46-65 | 165.1 ib | 57.2 ib | 9150 or 9450 ib |

| NC46-65 | 165.1 ib | 71.4 ib | 9150 or 9450 ib |

| NC46-67 | 171.4 ib | 57.2 ib | 9150 or 9450 ib |

| NC50-67 | 171.4 ib | 71.4 ib | 9150 or 9450 ib |

| NC50-70 | 177.8 ib | 57.2 ib | 9150 or 9450 ib |

| NC50-70 | 177.8 ib | 71.4 ib | 9150 or 9450 ib |

| NC50-72 | 184.2 ib | 71.4 ib | 9150 or 9450 ib |

| NC56-77 | 196.8 ib | 71.4 ib | 9150 or 9450 ib |

| NC56-80 | 203.2 ib | 71.4 ib | 9150 or 9450 ib |

| 6 5/8 REG | 209.6 ib | 71.4 ib | 9150 or 9450 ib |

| NC61-90 | 228.6 ib | 71.4 ib | 9150 or 9450 ib |

| 7 5/8 REG | 241.3 ib | 76.2 ib | 9150 or 9450 ib |

| NC70-97 | 247.6 ib | 76.2 ib | 9150 or 9450 ib |

| NC70-100 | 254.0 Nws | 76.2 ib | 9150 or 9450 ib |

| 8 5/8 REG | 279.4 ib | 76.2 ib | 9150 or 9450 ib |

Tsis Siv Neeg Magnetic Stabilizer

Integral non magnetic stabilizer yog tsim los ntawm ib qho khoom forging ntawm cov hlau tsis sib nqus. Cov khoom siv yog siab purity Chromium Manganese Austenitic stainless hlau.

Ultrasonic tshuaj xyuas thiab MPI tshuaj xyuas yog ua nyob rau hauv txhua forging tshaj nws tag nrho ntev thiab seem, tom qab ntxhib machining raws li API Spec 71. Mill xeem ntawv pov thawj nrog rau txhua yam khoom, tshuaj ntsuam xyuas, magnetic zog thiab soj ntsuam yog muab nrog tag nrho cov stabilizers.

Peb muaj lub peev xwm los tsim Cov Tsis Sib Nqus Stabilizer mus txog Crown OD 26 ''

Khoom Specification

| Tensile zog | Yield zog | Hardness | Sib nqus Permeability | |

| min. | min. | min. | MAX | Nruab nrab |

| 120 TSI | 100 KSI | 285 HB | 1.01 Nws | 1005 |

Non-Magnetic MWD Sub

Tsis yog Sib Nqus MWD Sub yog tsim los ntawm Chromium Manganese Austenitic stainless hlau, compressive stress resistance yeeb nkab yog tsim los ntawm cov khoom tsis siv rau kev txhim kho MWD impulser sab hauv thiab ntawm lwm tus. Tsis yog Sib Nqus MWD Sub tau dav siv los ntawm cov tuam txhab lag luam hauv tsev thiab thoob ntiaj teb.

Tag nrho cov kev sib txuas yog machined raws li API Spec.7-2 thiab xov cov hauv paus hniav yog txias ua hauj lwm thiab coated nrog API xov compound thiab nruab nrog tiv thaiv.

Khoom Specification

| Txoj kab uas hla (mm) | Sab hauv (mm) | Internal bore ntev (mm) | qis-kawg aperture (mm) | Tag nrho txoj cai (mm) |

| 121 | 88.2 ib | 1590 ib | 65 | 2500 |

| 172 | 111.5 ib | 1316 | 83 | 2073 ib |

| 175 | 127.4 ib | 1280 | 76 | 1690 |

| 203 | 127 | 1406 ib | 83 | 2048 ib |

LANDRILL Non-Magnetic Materials standard

Tsis yog Magnetic Properties:

Tus txheeb ze Permeability: Max 1.005

Kub Spot / Field Gradient: MAX ± 0.05μT

Kev Kho Mob Tshwj Xeeb ntawm ID: Roller Burnishing

Tom qab cov menyuam kub hnyiab, txheej txheej compressive tuaj ua, qhov zoo li hauv qab no:

Ua kom cov khoom tiv thaiv corrosion, Ua kom lub ntsej muag tawv ntawm qhov bore mus txog HB400, Ua kom tiav qhov kawg ntawm bore mus rau Ra≤3.2 μm, Kev Ntsuas thiab Kev Ntsuam Xyuas tau ua tiav ntawm txhua qhov bar thaum tsim NMDC, Stabilizer thiab MWD qhov chaw.

Chemical Composition, Tensile Test, Impact Test, Hardness Test, Metallographic Test (grain Size), Corrosion Test (Raws li ASTM A 262 Practice E), Ultrasonic Test hla tag nrho qhov ntev ntawm lub bar (raws li ASTM A 388), txheeb ze maganetic Permeability Test, Kub Spot Test, Dimensional Inspection, thiab lwm yam.

Cov kev xaiv tshwj xeeb ntawm qhov chaw kho mob: Rauj peening, roller burnishing, txhaj peening.

Room 703 Building B, Greenland center, Hi-tech development Zone Xi'an, Suav teb

Room 703 Building B, Greenland center, Hi-tech development Zone Xi'an, Suav teb 86-13609153141

86-13609153141